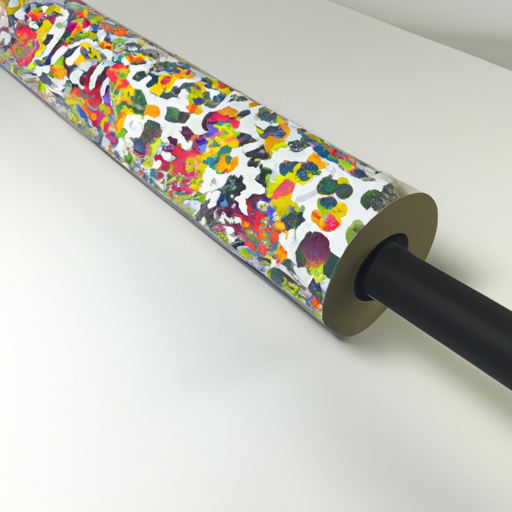

100 polyester fabric sublimation needle punched polyester felt roll manufactured by Chinese factory,

Table of Contents

How to Choose the Right 100% Polyester Fabric for Sublimation Needle Punched Felt Rolls

When selecting a 100% polyester fabric for sublimation needle punched felt rolls, it is important to consider several factors. First, the fabric should be of a high quality and have a tight weave to ensure that the colors of the sublimation process will be vibrant and long-lasting. Additionally, the fabric should be lightweight and durable, as it will be used for a variety of applications.

The fabric should also be able to withstand high temperatures, as the sublimation process requires temperatures of up to 400 degrees Fahrenheit. Additionally, the fabric should be able to resist fading and wear over time. Finally, the fabric should be easy to clean and maintain, as it will be used in a variety of environments.

When selecting a 100% polyester fabric for sublimation needle punched felt rolls, it is important to consider the quality of the fabric, its ability to withstand high temperatures, its resistance to fading and wear, and its ease of cleaning and maintenance. By taking these factors into consideration, you can ensure that you select the right fabric for your needs.

Exploring the Benefits of Sublimation Needle Punched Polyester Felt Rolls from Chinese Factories

Sublimation needle punched polyester felt rolls are becoming increasingly popular among Chinese factories due to their many benefits. This type of felt is made from polyester fibers that are punched together with a needle to create a strong, durable material. The felt is then sublimated, which is a process that uses heat and pressure to transfer a design or pattern onto the fabric. This process allows for a wide range of colors and patterns to be printed onto the felt, making it an ideal material for a variety of applications.

One of the main benefits of sublimation needle punched polyester felt rolls is their durability. The felt is highly resistant to wear and tear, making it an ideal choice for industrial applications. It is also resistant to water, oil, and other liquids, making it a great choice for outdoor applications. Additionally, the felt is flame retardant, making it a safe choice for use in areas where fire safety is a concern.

Another benefit of sublimation needle punched polyester felt rolls is their versatility. The felt can be used in a variety of applications, from automotive upholstery to home decor. It can also be used to create custom logos and designs, making it a great choice for businesses looking to create a unique look for their products.

Finally, sublimation needle punched polyester felt rolls are cost-effective. The felt is relatively inexpensive compared to other materials, making it a great choice for businesses looking to save money. Additionally, the felt is easy to work with, making it a great choice for those who are new to working with fabrics.

Overall, sublimation needle punched polyester felt rolls offer a variety of benefits to Chinese factories. The felt is durable, versatile, and cost-effective, making it an ideal choice for a variety of applications. With its many benefits, it is no wonder that this type of felt is becoming increasingly popular among Chinese factories.

Understanding the Manufacturing Process of 100% Polyester Fabric for Sublimation Needle Punched Felt Rolls

The manufacturing process of 100% polyester fabric for sublimation needle punched felt rolls is a complex and intricate process. It involves several steps that must be completed in order to produce a high-quality product.

The first step in the process is to create the polyester yarn. This is done by melting polyester pellets and spinning them into yarn. The yarn is then dyed to the desired color and then wound onto spools.

The next step is to create the fabric. This is done by weaving the yarn together on a loom. The fabric is then inspected for any defects and then cut into the desired size.

The fabric is then ready for the sublimation process. This involves printing a design onto the fabric using a special sublimation printer. The design is then heat-pressed onto the fabric, which causes the dye to transfer from the paper to the fabric.

The fabric is then ready for the needle punching process. This involves using a machine to punch small holes into the fabric. This creates a felt-like texture and helps to keep the fabric from fraying.

Finally, the fabric is rolled onto a spool and ready for sale. The finished product is a high-quality 100% polyester fabric for sublimation needle punched felt rolls. This fabric is perfect for a variety of applications, including upholstery, drapery, and more.