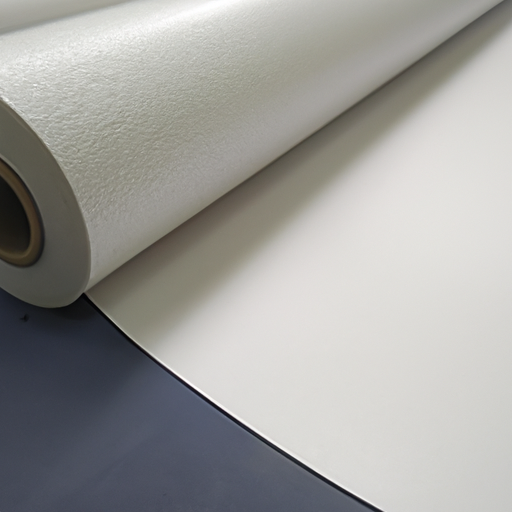

Vinyl polyester fabric, white adhesive backing felt roll, manufactured and wholesale in Chinese factories,

Table of Contents

Exploring the Benefits of Vinyl Polyester Fabric for Manufacturing and Wholesale in Chinese Factories

The use of vinyl polyester fabric in manufacturing and wholesale in Chinese factories is becoming increasingly popular due to its many benefits. Vinyl polyester fabric is a synthetic material that is lightweight, durable, and resistant to water, mildew, and fading. It is also highly resistant to abrasion and tearing, making it an ideal choice for a variety of applications.

The use of vinyl polyester fabric in Chinese factories offers a number of advantages. First, it is cost-effective. Vinyl polyester fabric is relatively inexpensive compared to other fabrics, making it an attractive option for manufacturers and wholesalers. Additionally, it is easy to work with and can be cut and sewn quickly and efficiently. This makes it an ideal choice for mass production.

Vinyl polyester fabric is also highly versatile. It can be used to create a variety of products, from clothing to furniture. It is also resistant to fading and mildew, making it an ideal choice for outdoor applications. Additionally, it is resistant to abrasion and tearing, making it a great choice for items that will be used frequently.

Finally, vinyl polyester fabric is environmentally friendly. It is made from recycled materials, making it a sustainable choice. Additionally, it is recyclable, making it an even more eco-friendly option.

In conclusion, vinyl polyester fabric is an ideal choice for manufacturers and wholesalers in Chinese factories due to its cost-effectiveness, versatility, and environmental friendliness. It is lightweight, durable, and resistant to water, mildew, and fading, making it an ideal choice for a variety of applications. Additionally, it is easy to work with and can be cut and sewn quickly and efficiently. Finally, it is made from recycled materials, making it a sustainable choice. For these reasons, vinyl polyester fabric is becoming increasingly popular in Chinese factories.

How to Choose the Right White Adhesive Backing Felt Roll for Your Manufacturing Needs

When it comes to manufacturing, choosing the right white adhesive backing felt roll is essential for achieving the desired results. The right felt roll can help to reduce noise, vibration, and friction, as well as provide a protective barrier between two surfaces. It is important to consider the specific needs of your manufacturing process when selecting the right white adhesive backing felt roll.

First, consider the size and shape of the felt roll. The size and shape of the felt roll will depend on the size and shape of the surfaces that need to be covered. If the surfaces are large, then a larger felt roll may be necessary. If the surfaces are small, then a smaller felt roll may be more suitable. Additionally, the shape of the felt roll should be considered. If the surfaces are curved, then a curved felt roll may be necessary.

Second, consider the type of adhesive backing that is needed. Different types of adhesive backing are available, such as pressure-sensitive adhesive, heat-activated adhesive, and water-activated adhesive. Pressure-sensitive adhesive is the most common type of adhesive backing and is suitable for most applications. Heat-activated adhesive is best for applications that require a strong bond, while water-activated adhesive is best for applications that require a temporary bond.

Third, consider the thickness of the felt roll. The thickness of the felt roll will depend on the amount of protection that is needed. If the surfaces need to be protected from heavy wear and tear, then a thicker felt roll may be necessary. If the surfaces need to be protected from light wear and tear, then a thinner felt roll may be more suitable.

Finally, consider the cost of the felt roll. Different types of felt rolls can vary in cost, so it is important to compare prices before making a purchase. Additionally, it is important to consider the quality of the felt roll. High-quality felt rolls will last longer and provide better protection than lower-quality felt rolls.

By considering the size, shape, type of adhesive backing, thickness, and cost of the felt roll, you can ensure that you select the right white adhesive backing felt roll for your manufacturing needs. With the right felt roll, you can reduce noise, vibration, and friction, as well as provide a protective barrier between two surfaces.

Understanding the Quality Control Process for Vinyl Polyester Fabric and White Adhesive Backing Felt Roll in Chinese Factories

The quality control process for vinyl polyester fabric and white adhesive backing felt roll in Chinese factories is a critical part of ensuring the highest quality products. Quality control is a process that involves inspecting and testing materials and products to ensure they meet the required standards. In Chinese factories, the quality control process for vinyl polyester fabric and white adhesive backing felt roll involves several steps.

First, the raw materials used to make the fabric and felt roll are inspected for quality. This includes checking for any defects in the material, such as holes, tears, or discoloration. The fabric and felt roll are then tested for strength and durability. This includes testing for tear strength, tensile strength, and abrasion resistance.

Next, the fabric and felt roll are inspected for color accuracy. This includes checking for any color variations or fading. The fabric and felt roll are then tested for shrinkage and stretchability. This includes testing for shrinkage after washing and stretching after use.

Finally, the fabric and felt roll are inspected for any defects in the adhesive backing. This includes checking for any air bubbles, wrinkles, or other imperfections. The adhesive backing is then tested for adhesion strength and durability.

These steps are essential for ensuring the highest quality vinyl polyester fabric and white adhesive backing felt roll in Chinese factories. By following these steps, manufacturers can ensure that their products meet the required standards and provide customers with the best possible product.