Polypropylene industrial wool felt backing adhesive needle punched felt roll set produced in China,

Table of Contents

The Benefits of Using Polypropylene Industrial Wool Felt Backing Adhesive Needle Punched Felt Roll Sets Produced in China

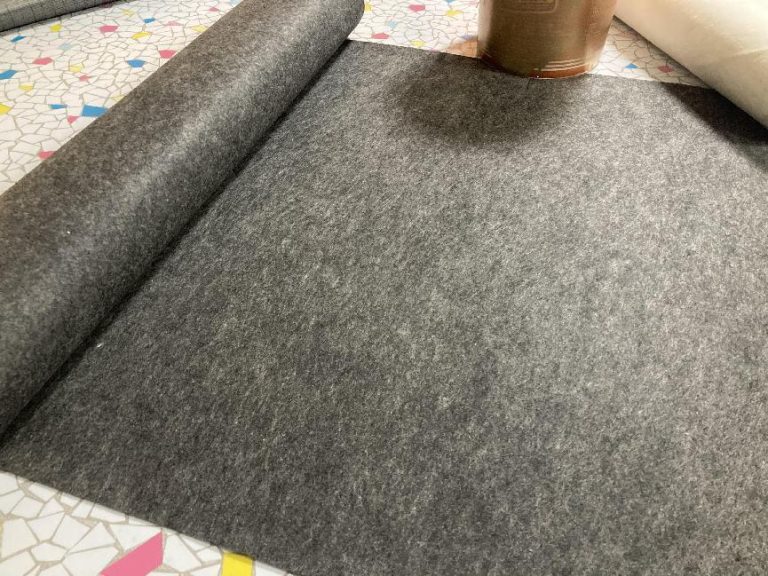

Polypropylene industrial wool felt backing adhesive needle punched felt roll sets produced in China offer a variety of benefits for businesses and individuals. These felt roll sets are made from high-quality polypropylene fibers that are needle punched together to form a strong and durable material. The felt roll sets are then coated with an adhesive backing to provide a secure and reliable bond between the felt and the surface it is being applied to.

The use of polypropylene industrial wool felt backing adhesive needle punched felt roll sets produced in China offers a number of advantages. Firstly, the felt roll sets are highly durable and can withstand a wide range of temperatures and conditions. This makes them ideal for use in a variety of industrial and commercial applications. Secondly, the felt roll sets are lightweight and easy to handle, making them ideal for use in a variety of applications. Thirdly, the felt roll sets are cost-effective and can be purchased in bulk, making them an economical choice for businesses and individuals.

The use of polypropylene industrial wool felt backing adhesive needle punched felt roll sets produced in China also offers a number of other benefits. The felt roll sets are resistant to water, oil, and other liquids, making them ideal for use in a variety of applications. Additionally, the felt roll sets are non-toxic and non-allergenic, making them safe for use in a variety of environments. Finally, the felt roll sets are easy to clean and maintain, making them an ideal choice for businesses and individuals who need a reliable and durable material for their projects.

Overall, polypropylene industrial wool felt backing adhesive needle punched felt roll sets produced in China offer a variety of benefits for businesses and individuals. These felt roll sets are highly durable, lightweight, cost-effective, and easy to clean and maintain. Additionally, the felt roll sets are non-toxic and non-allergenic, making them safe for use in a variety of environments. As such, these felt roll sets are an ideal choice for businesses and individuals who need a reliable and durable material for their projects.

How to Choose the Right Polypropylene Industrial Wool Felt Backing Adhesive Needle Punched Felt Roll Set for Your Project

When selecting the right polypropylene industrial wool felt backing adhesive needle punched felt roll set for your project, there are several factors to consider. First, you should consider the size and shape of the felt roll set. The size and shape of the felt roll set will determine the amount of coverage you need for your project. Additionally, the size and shape of the felt roll set will also determine the amount of adhesive needed to secure the felt roll set in place.

Next, you should consider the type of adhesive used to secure the felt roll set. Different adhesives have different levels of strength and durability, so it is important to select an adhesive that is suitable for your project. Additionally, you should consider the type of surface the felt roll set will be applied to. Different surfaces require different adhesives, so it is important to select an adhesive that is suitable for the surface you are working with.

Finally, you should consider the type of needle punching used to secure the felt roll set. Different needle punching techniques have different levels of strength and durability, so it is important to select a needle punching technique that is suitable for your project. Additionally, you should consider the type of backing material used to secure the felt roll set. Different backing materials have different levels of strength and durability, so it is important to select a backing material that is suitable for your project.

By considering these factors, you can ensure that you select the right polypropylene industrial wool felt backing adhesive needle punched felt roll set for your project. With the right felt roll set, you can ensure that your project is completed with the highest level of quality and durability.

Exploring the Manufacturing Process of Polypropylene Industrial Wool Felt Backing Adhesive Needle Punched Felt Roll Sets in China

The manufacturing process of polypropylene industrial wool felt backing adhesive needle punched felt roll sets in China is a complex and intricate process. It involves several steps, each of which must be completed with precision and accuracy in order to ensure the highest quality product.

The first step in the manufacturing process is the selection of the raw materials. The raw materials used in the production of polypropylene industrial wool felt backing adhesive needle punched felt roll sets in China include polypropylene, wool, and adhesive. The polypropylene is used to create the felt backing, while the wool is used to create the felt material. The adhesive is used to bind the two materials together.

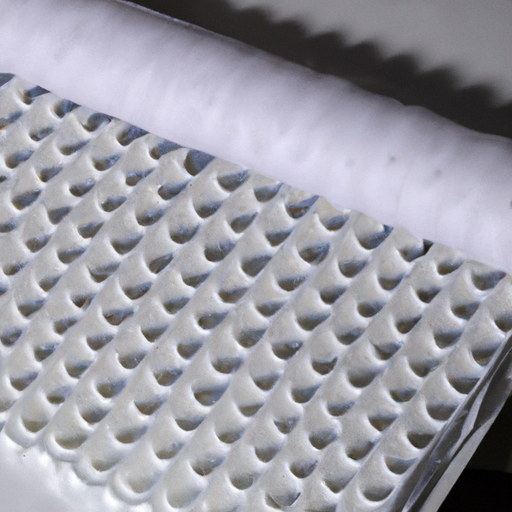

Once the raw materials have been selected, they are then cut into the desired shapes and sizes. The felt material is then punched with needles to create the desired pattern. This process is known as needle punching. The needle punching process is used to create a strong bond between the felt material and the backing material.

The next step in the manufacturing process is the application of the adhesive. The adhesive is applied to the felt material and the backing material in order to create a strong bond between the two materials. The adhesive is then cured in order to ensure that it is completely dry and secure.

The final step in the manufacturing process is the assembly of the felt roll sets. The felt material is cut into the desired shapes and sizes and then placed onto the backing material. The adhesive is then applied to the felt material and the backing material in order to create a strong bond between the two materials. The felt roll sets are then inspected for quality assurance before being packaged and shipped to customers.

The manufacturing process of polypropylene industrial wool felt backing adhesive needle punched felt roll sets in China is a complex and intricate process. It requires precision and accuracy in order to ensure the highest quality product. By following the steps outlined above, manufacturers can ensure that their products are of the highest quality and meet the needs of their customers.