China factory made white fiber composite bonded felt than acrylic, oil absorbent wool felt rolled

Table of Contents

How China Factory Made White Fiber Composite Bonded Felt is Revolutionizing Oil Absorbency

The use of white fiber composite bonded felt is revolutionizing the way oil is absorbed. This innovative material is made in factories in China and is quickly becoming the preferred choice for oil absorbency.

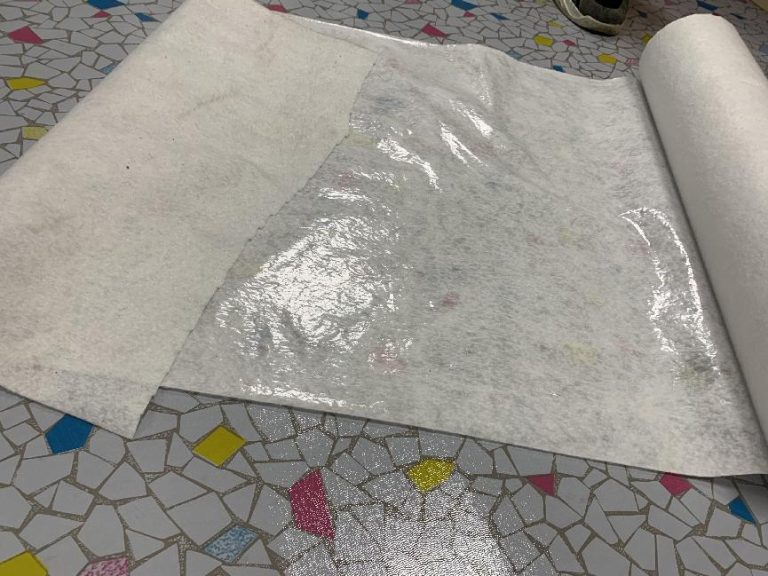

White fiber composite bonded felt is a combination of two materials: polyester and rayon. The polyester provides strength and durability, while the rayon provides absorbency. This combination of materials creates a material that is both strong and absorbent, making it ideal for oil absorbency.

The material is made in a factory in China, where it is cut into sheets and then bonded together. This process creates a material that is both strong and absorbent, making it ideal for oil absorbency. The material is then treated with a special coating that helps it to resist water and oil. This coating also helps to reduce the amount of oil that is absorbed, making it more efficient at absorbing oil.

The material is also lightweight and easy to transport, making it ideal for use in a variety of applications. It can be used in industrial settings, such as oil spills, or in residential settings, such as for cleaning up spills in the kitchen.

White fiber composite bonded felt is revolutionizing the way oil is absorbed. Its combination of strength and absorbency makes it ideal for a variety of applications, and its lightweight and easy to transport nature makes it ideal for use in a variety of settings. This innovative material is quickly becoming the preferred choice for oil absorbency, and its use is revolutionizing the way oil is absorbed.

Exploring the Benefits of Using China Factory Made White Fiber Composite Bonded Felt for Industrial Applications

The use of white fiber composite bonded felt in industrial applications has become increasingly popular in recent years due to its many benefits. This material is made from a combination of natural and synthetic fibers that are bonded together with a special adhesive. The resulting material is lightweight, durable, and highly resistant to wear and tear. It is also highly absorbent, making it ideal for use in a variety of industrial applications.

One of the primary benefits of using white fiber composite bonded felt is its ability to reduce noise levels. This material is able to absorb sound waves, making it an ideal choice for use in industrial settings where noise levels can be a problem. It is also highly resistant to heat, making it suitable for use in areas where temperatures can fluctuate. Additionally, this material is highly resistant to abrasion, making it an ideal choice for use in areas where there is a risk of wear and tear.

Another benefit of using white fiber composite bonded felt is its ability to provide insulation. This material is able to trap air, making it an ideal choice for use in areas where insulation is needed. Additionally, this material is highly resistant to moisture, making it an ideal choice for use in areas where moisture can be a problem.

Finally, white fiber composite bonded felt is highly cost-effective. This material is produced in China, making it an affordable option for industrial applications. Additionally, this material is highly durable, making it an ideal choice for use in areas where it will be exposed to a variety of conditions.

In conclusion, white fiber composite bonded felt is an ideal choice for use in industrial applications due to its many benefits. This material is lightweight, durable, and highly resistant to wear and tear. Additionally, it is highly absorbent, making it an ideal choice for use in areas where noise levels can be a problem. Additionally, this material is highly resistant to heat and moisture, making it an ideal choice for use in areas where insulation and moisture control are needed. Finally, this material is highly cost-effective, making it an affordable option for industrial applications.