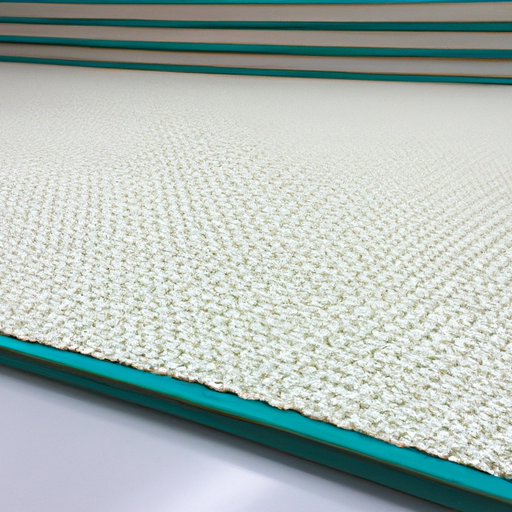

Acrylic coating and fabric softener, backing adhesive felt roll, a high-quality factory in China,

Table of Contents

How Acrylic Coating and Fabric Softener Can Improve the Quality of Your Backing Adhesive Felt Roll

Acrylic coating and fabric softener can be used to improve the quality of your backing adhesive felt roll. Acrylic coating is a type of protective coating that is applied to the felt roll to provide a barrier against dirt, dust, and other contaminants. This coating also helps to reduce the amount of static electricity that builds up on the felt roll, which can cause it to stick to itself and other surfaces. Fabric softener is also used to improve the quality of the felt roll. It helps to make the felt softer and more pliable, which makes it easier to work with. Additionally, fabric softener helps to reduce the amount of static electricity that builds up on the felt roll, which can cause it to stick to itself and other surfaces.

When applying acrylic coating and fabric softener to your backing adhesive felt roll, it is important to follow the manufacturer’s instructions. Generally, the felt roll should be cleaned and dried before applying the coating and softener. The coating should be applied in a thin, even layer and allowed to dry completely before applying the fabric softener. The fabric softener should be applied in a thin, even layer and allowed to dry completely before using the felt roll.

Using acrylic coating and fabric softener on your backing adhesive felt roll can help to improve its quality and make it easier to work with. It can also help to reduce the amount of static electricity that builds up on the felt roll, which can cause it to stick to itself and other surfaces. By following the manufacturer’s instructions and taking the time to properly apply the coating and softener, you can ensure that your felt roll is of the highest quality.

Exploring the Benefits of Working with a High-Quality Factory in China for Your Acrylic Coating and Fabric Softener Needs

When it comes to finding a reliable and high-quality factory in China for your acrylic coating and fabric softener needs, there are many benefits to be gained. Working with a factory in China can provide you with access to a wide range of products, competitive prices, and a reliable supply chain. Here, we will explore the advantages of working with a high-quality factory in China for your acrylic coating and fabric softener needs.

One of the primary benefits of working with a factory in China is the access to a wide range of products. Chinese factories are renowned for their ability to produce a variety of products, from acrylic coatings to fabric softeners. This means that you can find the exact product you need, without having to compromise on quality or price. Additionally, Chinese factories are often able to produce custom products to meet your specific needs.

Another advantage of working with a factory in China is the competitive prices they offer. Chinese factories are able to produce products at a lower cost than many other countries, due to their lower labor costs and access to raw materials. This means that you can get the same quality product at a fraction of the cost. Additionally, Chinese factories often offer discounts for bulk orders, allowing you to save even more money.

Finally, working with a factory in China can provide you with a reliable supply chain. Chinese factories are known for their efficient production processes and their ability to meet tight deadlines. This means that you can be sure that your orders will be delivered on time and in the exact quantity you need. Additionally, Chinese factories are often willing to work with you to ensure that your products meet all of your specifications.

In conclusion, there are many benefits to be gained from working with a high-quality factory in China for your acrylic coating and fabric softener needs. From access to a wide range of products to competitive prices and a reliable supply chain, working with a factory in China can provide you with the products you need at a price you can afford.

Tips for Choosing the Right Backing Adhesive Felt Roll for Your Acrylic Coating and Fabric Softener Projects

1. Consider the type of fabric you are working with. Different fabrics require different types of backing adhesive felt rolls. For example, natural fabrics such as cotton and linen require a more flexible backing adhesive felt roll, while synthetic fabrics such as polyester and nylon require a more rigid backing adhesive felt roll.

2. Consider the weight of the fabric. Heavier fabrics require a more robust backing adhesive felt roll, while lighter fabrics require a lighter backing adhesive felt roll.

3. Consider the type of acrylic coating or fabric softener you are using. Different types of acrylic coatings and fabric softeners require different types of backing adhesive felt rolls. For example, some acrylic coatings require a more flexible backing adhesive felt roll, while some fabric softeners require a more rigid backing adhesive felt roll.

4. Consider the size of the project. If you are working on a large project, you may need to use a larger backing adhesive felt roll. Conversely, if you are working on a smaller project, you may need to use a smaller backing adhesive felt roll.

5. Consider the environment in which you are working. Different environments require different types of backing adhesive felt rolls. For example, if you are working in a humid environment, you may need to use a more moisture-resistant backing adhesive felt roll.

6. Consider the cost of the backing adhesive felt roll. Different types of backing adhesive felt rolls can vary in cost, so it is important to consider your budget when selecting the right backing adhesive felt roll for your project.