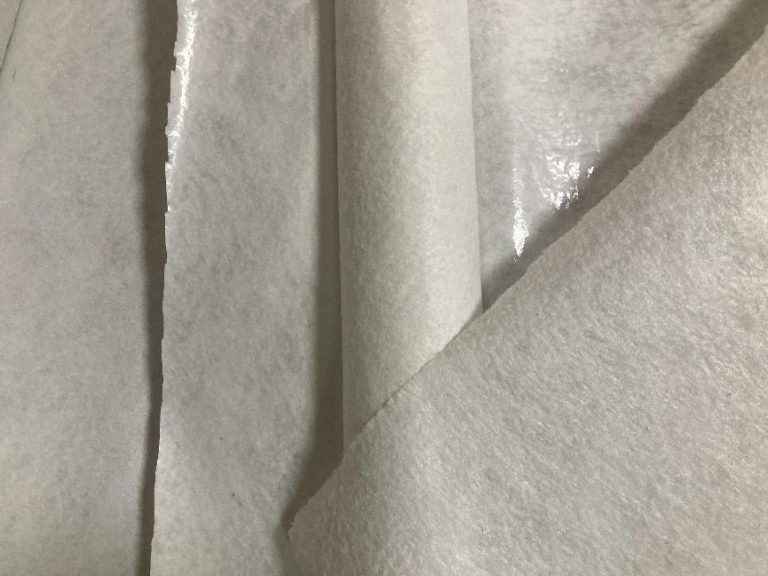

Ecological felt fabric, white self-adhesive felt roll, produced and manufactured by Chinese factories

Table of Contents

Exploring the Benefits of Ecological Felt Fabric: How It Can Help Reduce Environmental Impact

The environmental impact of the fashion industry is a growing concern for many people. As the demand for clothing continues to rise, so does the amount of resources needed to produce it. Ecological felt fabric is a sustainable alternative to traditional fabrics that can help reduce the environmental impact of the fashion industry.

Ecological felt fabric is made from natural fibers such as wool, cotton, and bamboo. Unlike traditional fabrics, ecological felt fabric does not require the use of harsh chemicals or dyes during the manufacturing process. This makes it a much more eco-friendly option. Additionally, ecological felt fabric is biodegradable, meaning it can be broken down naturally over time. This helps to reduce the amount of waste that is produced during the manufacturing process.

Ecological felt fabric is also incredibly durable. It is resistant to wear and tear, meaning it can last for years without needing to be replaced. This helps to reduce the amount of clothing that needs to be produced, which in turn reduces the amount of resources needed to make it. Additionally, ecological felt fabric is breathable and lightweight, making it a comfortable and practical choice for clothing.

Finally, ecological felt fabric is an affordable option for those looking to reduce their environmental impact. It is often cheaper than traditional fabrics, making it a great choice for those on a budget.

Overall, ecological felt fabric is a great option for those looking to reduce their environmental impact. It is made from natural fibers, does not require the use of harsh chemicals or dyes, is biodegradable, durable, breathable, and lightweight, and is an affordable option. By choosing ecological felt fabric, you can help reduce the environmental impact of the fashion industry.

The Rise of White Self-Adhesive Felt Roll: How It’s Revolutionizing the Textile Industry

The textile industry has seen a revolution in recent years with the rise of white self-adhesive felt roll. This innovative product has revolutionized the way fabrics are used in a variety of applications, from clothing to home décor.

White self-adhesive felt roll is a versatile material that can be used for a variety of purposes. It is made from a combination of polyester and acrylic fibers, which are then bonded together with a special adhesive. This adhesive allows the felt to be easily cut and shaped into any desired shape or size. The adhesive also makes it possible to adhere the felt to a variety of surfaces, including fabric, wood, metal, and plastic.

The versatility of white self-adhesive felt roll makes it an ideal choice for a variety of applications. It can be used to create clothing, such as jackets, skirts, and dresses. It can also be used to create home décor items, such as curtains, rugs, and wall hangings. It can even be used to create custom-made furniture pieces.

The adhesive properties of white self-adhesive felt roll make it an ideal choice for a variety of industries. It is often used in the automotive industry to create soundproofing materials, as well as to line the interior of vehicles. It is also used in the construction industry to create insulation and soundproofing materials.

The use of white self-adhesive felt roll has revolutionized the textile industry. It is a versatile material that can be used for a variety of purposes, from clothing to home décor. Its adhesive properties make it an ideal choice for a variety of industries, from automotive to construction. With its versatility and adhesive properties, white self-adhesive felt roll is revolutionizing the textile industry.

Chinese Factories: The Pros and Cons of Manufacturing Ecological Felt Fabric and White Self-Adhesive Felt Roll

The use of felt fabric and felt rolls has become increasingly popular in recent years due to their versatility and durability. As a result, many companies have begun to manufacture these products in Chinese factories. While this can be a cost-effective way to produce these items, there are both pros and cons to consider when deciding to manufacture ecological felt fabric and white self-adhesive felt roll in Chinese factories.

One of the primary advantages of manufacturing these products in Chinese factories is the cost savings. Chinese factories are able to produce these items at a much lower cost than factories in other countries, making them an attractive option for companies looking to reduce their production costs. Additionally, Chinese factories often have access to a wide variety of materials, allowing them to produce high-quality products at a lower cost.

On the other hand, there are some potential drawbacks to consider when manufacturing ecological felt fabric and white self-adhesive felt roll in Chinese factories. One of the primary concerns is the quality of the materials used. Chinese factories may not always use the highest quality materials, which could lead to inferior products. Additionally, there is the potential for environmental issues due to the lack of regulation in Chinese factories. This could lead to the release of hazardous chemicals into the environment, which could have a negative impact on the environment and human health.

Overall, there are both pros and cons to consider when deciding to manufacture ecological felt fabric and white self-adhesive felt roll in Chinese factories. Companies should weigh the cost savings against the potential risks before making a decision. By doing so, they can ensure that they are producing high-quality products while also protecting the environment and human health.