Enhancing Wooden Furniture Quality with Non-Woven Wool Laminated White PE Coating

In the competitive world of wooden furniture manufacturing, selecting the right materials for protection, aesthetics, and functionality is critical. Non-woven wool laminated with white PE (polyethylene) coating has emerged as a superior choice for manufacturers aiming to elevate product durability, design, and customer satisfaction. This innovative material combines the natural benefits of wool with the protective qualities of polyethylene, offering a versatile solution for modern furniture production. In this blog, we explore its advantages, applications, and key considerations for integrating it into your manufacturing process.

Table of Contents

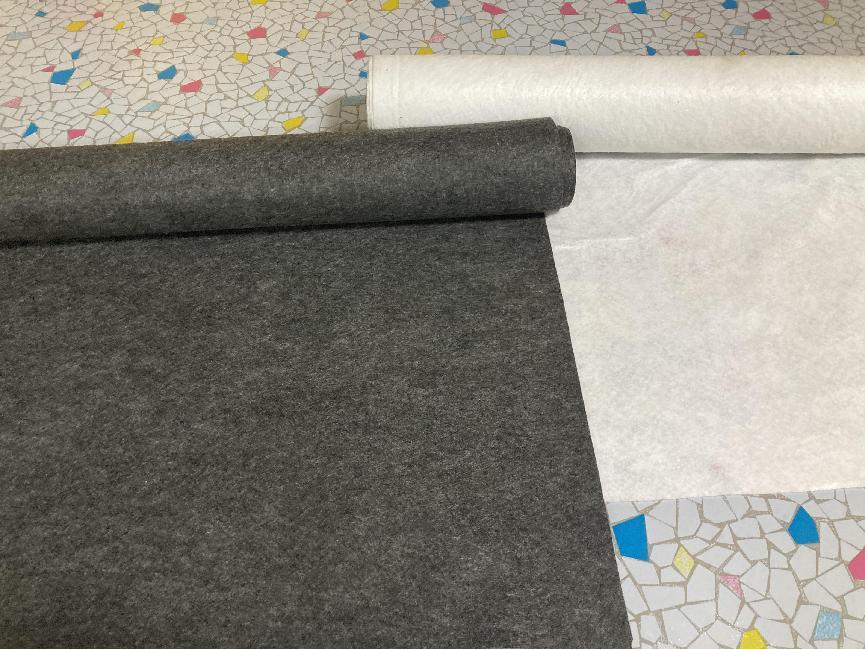

What Is Non-Woven Wool Laminated with White PE Coating?

Non-woven wool laminated with white PE coating is a hybrid material crafted by bonding breathable, flexible non-woven wool fibers to a thin layer of polyethylene. The result is a durable, water-resistant sheet with a smooth, clean white finish. This combination leverages the innate resilience of wool and the moisture-blocking properties of PE, making it ideal for safeguarding and enhancing wooden furniture.

Key Benefits for Wooden Furniture Manufacturers

- Exceptional Durability

The non-woven wool base provides excellent shock absorption and resistance to abrasion, protecting furniture surfaces from scratches and dents during production, shipping, or daily use.

- Moisture & Stain Resistance

The PE coating acts as a barrier against spills, humidity, and stains, preserving the integrity of wood finishes in humid environments or high-traffic settings.

- Aesthetic Versatility

The neutral white finish offers a clean, modern appearance that complements any design. It can be left as-is for a minimalist look or easily painted/printed to align with custom branding.

- Lightweight & Flexible

Easy to cut, shape, and apply, this material adapts seamlessly to curved edges, drawers, shelves, and upholstered components without adding bulk.

- Eco-Friendly Potential

Many non-woven wool variants incorporate recycled fibers, while PE coatings can be engineered for recyclability, supporting sustainable manufacturing practices.

- Cost Efficiency

Long-lasting performance reduces the need for frequent replacements, lowering long-term material costs for manufacturers and end-users alike.

Applications in Wooden Furniture Manufacturing

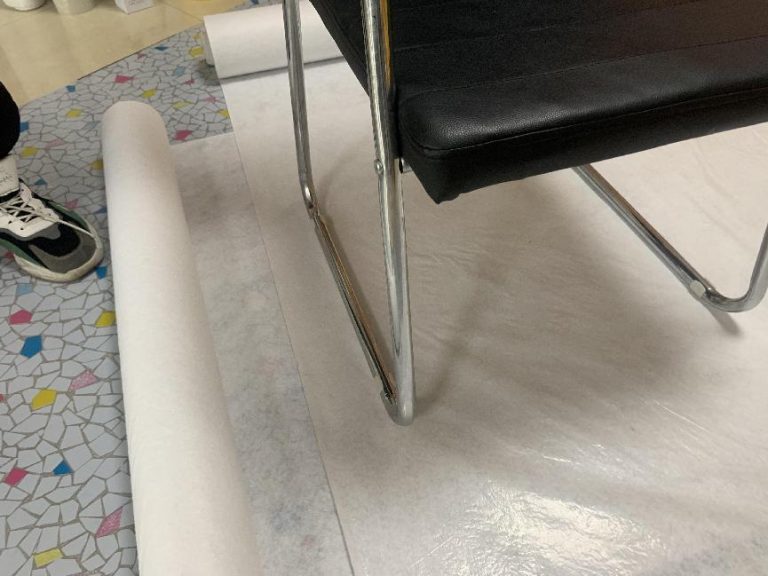

- Protective Wrapping: Shield furniture surfaces during transit or storage

- Drawer & Shelf Liners: Prevent scratches and dampness while enhancing visual appeal.

- Upholstery Backing: Add cushioning and moisture resistance to padded furniture.

- Cabinet Interiors: Line cabinets to protect against wear and humidity.

- Decorative Panels: Use as a base for veneers or laminated designs.

Why Choose This Material Over Alternatives?

Traditional options like plain felt, plastic sheets, or foam lack the balanced combination of breathability, protection, and design flexibility offered by non-woven wool/PE laminates. Unlike plastic, which can trap moisture, or basic fabrics that fray easily, this material ensures lasting performance without compromising aesthetics.

Choosing the Right Supplier: Key Considerations

- Material Quality: Verify tensile strength, moisture resistance, and adhesive properties through samples or certifications (e.g., ISO, SGS).

- Customization: Opt for suppliers offering tailored thicknesses, sheet sizes, or adhesive backing to meet specific design needs.

- Sustainability: Prioritize manufacturers using recycled wool fibers or eco-friendly PE coatings.

- Scalability: Ensure consistent supply and competitive pricing for bulk orders.

- Technical Support: Partner with suppliers who provide guidance on optimal application techniques.

Final Thoughts

Non-woven wool laminated with white PE coating represents a strategic upgrade for wooden furniture manufacturers seeking to balance practicality with premium aesthetics. Its unique blend of durability, moisture resistance, and design adaptability makes it a cost-effective solution for enhancing product longevity and customer satisfaction.

By collaborating with reputable suppliers who prioritize quality and innovation, manufacturers can integrate this material into their workflows confidently, ensuring their furniture stands out in both form and function.