Industrial sewing machines, felt rolls, adhesive protective floor coverings, China’s low-cost factory

Table of Contents

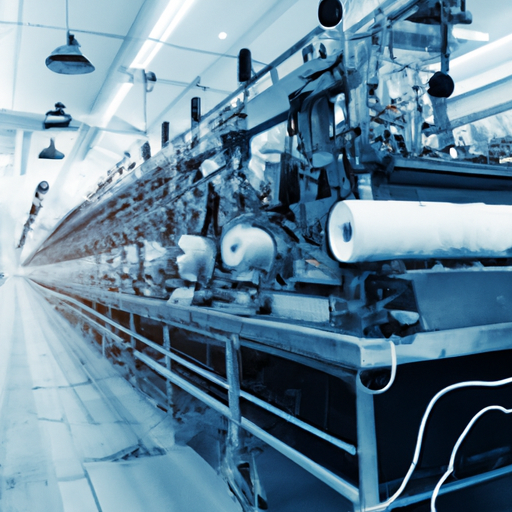

How Industrial Sewing Machines are Revolutionizing the Textile Industry

The textile industry has seen a revolution in recent years, thanks to the introduction of industrial sewing machines. These machines have revolutionized the way textiles are produced, allowing for faster, more efficient production.

Industrial sewing machines are designed to handle large-scale production of textiles. They are capable of stitching together large pieces of fabric quickly and accurately, making them ideal for mass production. These machines are also designed to be more durable and reliable than traditional sewing machines, allowing them to handle the rigors of industrial production.

The introduction of industrial sewing machines has allowed for faster production of textiles. These machines are capable of stitching together large pieces of fabric quickly and accurately, allowing for faster production times. This has allowed for increased efficiency in the production process, allowing for more textiles to be produced in a shorter amount of time.

Industrial sewing machines have also allowed for increased quality in the production of textiles. These machines are designed to be more accurate and reliable than traditional sewing machines, allowing for more precise stitching and fewer errors. This has allowed for higher quality textiles to be produced, resulting in better products for consumers.

Finally, industrial sewing machines have allowed for increased safety in the production of textiles. These machines are designed to be safer than traditional sewing machines, reducing the risk of injury to workers. This has allowed for a safer working environment, resulting in fewer accidents and injuries in the workplace.

Overall, industrial sewing machines have revolutionized the textile industry. These machines have allowed for faster, more efficient production of textiles, as well as increased quality and safety. As a result, the textile industry has seen a revolution in recent years, thanks to the introduction of industrial sewing machines.

Exploring the Benefits of Felt Rolls for Industrial Applications

Felt rolls are a versatile and cost-effective material used in a variety of industrial applications. They are made from a variety of materials, including wool, polyester, and acrylic, and are available in a range of thicknesses and densities. Felt rolls are used in a variety of industries, including automotive, aerospace, and manufacturing.

Felt rolls offer a number of benefits for industrial applications. They are highly durable and resistant to wear and tear, making them ideal for use in high-traffic areas. They are also resistant to moisture, making them suitable for use in wet environments. Felt rolls are also non-abrasive, making them ideal for use in applications where delicate surfaces need to be protected.

Felt rolls are also highly versatile and can be cut to any size or shape. This makes them ideal for use in custom applications, such as gaskets, seals, and insulation. They can also be used to line surfaces, such as shelves and drawers, to protect them from scratches and other damage.

Felt rolls are also cost-effective. They are relatively inexpensive compared to other materials, making them a cost-effective solution for many industrial applications. They are also easy to install and maintain, making them a convenient choice for many businesses.

In conclusion, felt rolls are an ideal material for a variety of industrial applications. They are highly durable, versatile, and cost-effective, making them an ideal choice for businesses looking for a reliable and cost-effective solution.

The Advantages of Adhesive Protective Floor Coverings in Industrial Settings

Adhesive protective floor coverings are an invaluable asset in industrial settings. These coverings provide a number of advantages that make them an ideal choice for protecting floors from damage and wear.

The primary advantage of adhesive protective floor coverings is their durability. These coverings are designed to withstand heavy foot traffic and the wear and tear of industrial equipment. They are also resistant to chemicals, oils, and other substances that may be present in industrial settings. This makes them an ideal choice for protecting floors from damage and wear.

Another advantage of adhesive protective floor coverings is their ease of installation. These coverings are designed to be applied quickly and easily, without the need for specialized tools or equipment. This makes them an ideal choice for industrial settings where time is of the essence.

Adhesive protective floor coverings also provide a high level of safety. These coverings are designed to provide a slip-resistant surface, reducing the risk of slips and falls. This makes them an ideal choice for industrial settings where safety is a priority.

Finally, adhesive protective floor coverings are cost-effective. These coverings are designed to be long-lasting and require minimal maintenance. This makes them an ideal choice for industrial settings where budgets are tight.

In conclusion, adhesive protective floor coverings are an invaluable asset in industrial settings. These coverings provide a number of advantages that make them an ideal choice for protecting floors from damage and wear. They are durable, easy to install, provide a high level of safety, and are cost-effective. For these reasons, adhesive protective floor coverings are an ideal choice for industrial settings.