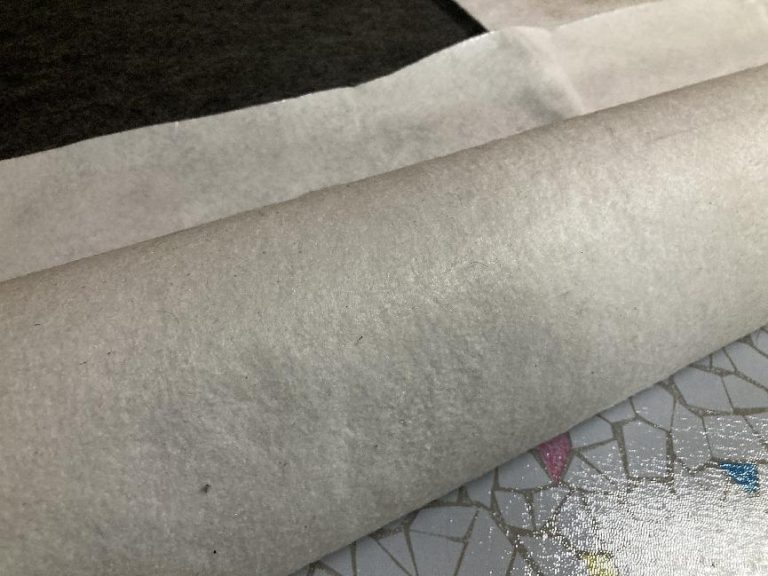

Oil absorbent wool felt roller applicator, self-adhesive felt roll 1m×50m prefabric best factory made

Table of Contents

How Oil Absorbent Wool Felt Roller Applicators Can Help Keep Your Workplace Clean and Safe

Oil absorbent wool felt roller applicators are an essential tool for keeping workplaces clean and safe. These applicators are designed to quickly and effectively absorb oil, grease, and other liquids from a variety of surfaces. They are ideal for use in industrial, automotive, and other commercial settings.

Oil absorbent wool felt roller applicators are made from a combination of wool and synthetic fibers. The wool fibers are highly absorbent and can quickly soak up oil and other liquids. The synthetic fibers provide strength and durability, making the applicators suitable for use in a variety of environments.

The applicators are easy to use and can be used on a variety of surfaces. They can be used on floors, walls, and other surfaces to quickly and effectively absorb oil and other liquids. The applicators can also be used to clean up spills and other messes.

Using oil absorbent wool felt roller applicators can help keep workplaces clean and safe. The applicators can quickly and effectively absorb oil and other liquids, preventing them from spreading and creating a hazardous environment. This can help reduce the risk of slips and falls, as well as the risk of fire and other accidents.

In addition, using oil absorbent wool felt roller applicators can help reduce the amount of time and money spent on cleaning up messes. The applicators can quickly and effectively absorb oil and other liquids, reducing the amount of time and effort needed to clean up spills and other messes. This can help save money on cleaning supplies and labor costs.

Overall, oil absorbent wool felt roller applicators are an essential tool for keeping workplaces clean and safe. They can quickly and effectively absorb oil and other liquids, reducing the risk of slips and falls, as well as the risk of fire and other accidents. In addition, they can help reduce the amount of time and money spent on cleaning up messes.

The Benefits of Using Self-Adhesive Felt Rolls for Industrial Applications

Self-adhesive felt rolls are a versatile and cost-effective material for industrial applications. They are made from a combination of synthetic and natural fibers, which are then bonded together with a pressure-sensitive adhesive. This adhesive allows the felt to be easily applied to a variety of surfaces, making it an ideal choice for a wide range of industrial applications.

The primary benefit of using self-adhesive felt rolls is their ability to provide a protective layer between two surfaces. This layer helps to reduce friction and wear, which can extend the life of the components and reduce the need for costly repairs or replacements. Additionally, the felt can be used to dampen vibrations and absorb shock, making it an ideal choice for applications that require a high degree of protection.

Self-adhesive felt rolls are also highly durable and resistant to a variety of environmental conditions. This makes them an ideal choice for outdoor applications, as they can withstand exposure to moisture, UV rays, and extreme temperatures. Additionally, the felt is resistant to most chemicals, making it suitable for use in industrial settings.

The adhesive backing of self-adhesive felt rolls also makes them easy to install. The felt can be cut to size and applied directly to the surface, eliminating the need for additional tools or equipment. This makes the felt an ideal choice for applications that require quick and easy installation.

Finally, self-adhesive felt rolls are an economical choice for industrial applications. The felt is available in a variety of thicknesses and densities, allowing users to select the material that best meets their needs. Additionally, the felt is relatively inexpensive, making it a cost-effective choice for a wide range of applications.

In conclusion, self-adhesive felt rolls are an ideal choice for industrial applications. They provide a protective layer between two surfaces, are highly durable and resistant to environmental conditions, and are easy to install. Additionally, the felt is an economical choice, making it a cost-effective solution for a variety of applications.