Peel and stick ceramic tile pads, roll blue and white self-adhesive felt rolls, factory in China

Table of Contents

How Peel and Stick Ceramic Tile Pads Can Transform Your Home Decor

Peel and stick ceramic tile pads are an innovative and cost-effective way to transform the look of any room in your home. These pads are made from a durable, waterproof material that can be easily applied to any flat surface. They come in a variety of colors and patterns, allowing you to customize the look of your home decor.

The installation process is simple and straightforward. All you need to do is peel off the backing and press the pad onto the desired surface. The adhesive on the back of the pad will hold it in place, and you can easily trim it to fit any size or shape. The pads are also easy to remove, so you can change up your decor whenever you want.

The pads are also incredibly versatile. You can use them to create a backsplash in your kitchen, a feature wall in your living room, or even a decorative border in your bathroom. They are also great for covering up any imperfections in your walls, such as cracks or chips.

The pads are also incredibly durable and long-lasting. They are resistant to water, heat, and humidity, so they won’t fade or peel over time. They are also easy to clean, so you don’t have to worry about dirt or grime building up.

Peel and stick ceramic tile pads are an affordable and easy way to give any room in your home a fresh new look. With their versatility and durability, they are sure to be a great addition to your home decor.

The Benefits of Using Roll Blue and White Self-Adhesive Felt Rolls

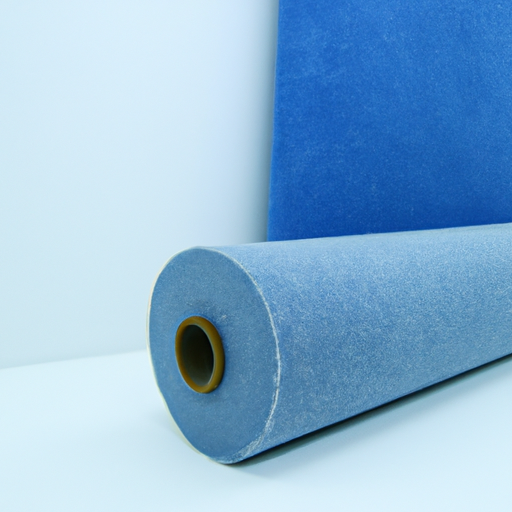

Roll blue and white self-adhesive felt rolls are a great way to add a unique touch to any project. These rolls are made from a durable, high-quality felt material that is easy to apply and remove. They come in a variety of sizes and colors, making them perfect for any project.

The first benefit of using roll blue and white self-adhesive felt rolls is that they are easy to use. The adhesive backing makes them simple to apply and remove, and they can be cut to fit any size or shape. This makes them ideal for a variety of projects, from scrapbooking to home décor.

Another benefit of using roll blue and white self-adhesive felt rolls is that they are highly durable. The felt material is designed to withstand wear and tear, making it perfect for projects that require a lot of use. This makes them ideal for projects that require a lot of movement, such as furniture or wall art.

The third benefit of using roll blue and white self-adhesive felt rolls is that they are cost-effective. The rolls are relatively inexpensive, making them a great choice for those on a budget. They are also easy to find, as they are widely available in craft stores and online.

Finally, roll blue and white self-adhesive felt rolls are a great way to add a unique touch to any project. The felt material is available in a variety of colors, allowing you to customize your project to fit your style. This makes them perfect for adding a personal touch to any project.

Overall, roll blue and white self-adhesive felt rolls are a great choice for any project. They are easy to use, highly durable, cost-effective, and can be customized to fit any style. With these benefits, it is easy to see why these rolls are a popular choice for many projects.

Exploring the Manufacturing Process of Peel and Stick Ceramic Tile Pads in China

The manufacturing process of peel and stick ceramic tile pads in China is a complex and intricate process that requires a great deal of skill and precision. The process begins with the selection of the raw materials, which are typically ceramic, adhesive, and backing paper. The ceramic is then cut into the desired shape and size, and the adhesive is applied to the back of the tile. The backing paper is then applied to the adhesive side of the tile, and the tile is then placed in a press to ensure a secure bond between the adhesive and the tile.

Once the tile is pressed, it is then inspected for any defects or imperfections. If any are found, the tile is discarded and the process begins again. If the tile passes inspection, it is then ready for packaging. The tile is placed in a box or bag and sealed to ensure that it remains secure during shipping.

The next step in the manufacturing process is the application of a protective coating to the tile. This coating helps to protect the tile from scratches and other damage that may occur during shipping or installation. The coating is typically applied by a machine that sprays the coating onto the tile.

Finally, the tile is ready for shipment. The tile is carefully packaged and shipped to its destination. Once it arrives, it is ready to be installed in its intended location.

The manufacturing process of peel and stick ceramic tile pads in China is a complex and intricate process that requires a great deal of skill and precision. By following the steps outlined above, manufacturers can ensure that their products are of the highest quality and will provide years of use and enjoyment.