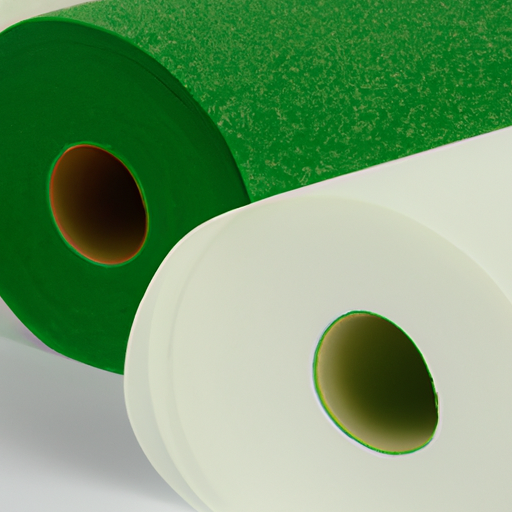

Polyester self-adhesive felt rolls with rubber backing, white and green, manufactured in Chinese factories,

Table of Contents

How Polyester Self-Adhesive Felt Rolls with Rubber Backing are Revolutionizing the Manufacturing Industry

The manufacturing industry is undergoing a revolution, thanks to the introduction of polyester self-adhesive felt rolls with rubber backing. This innovative material is revolutionizing the way manufacturers produce products, allowing them to create higher quality items with greater efficiency.

Polyester self-adhesive felt rolls with rubber backing are made from a combination of polyester and rubber. The polyester provides a strong, durable material that is resistant to wear and tear, while the rubber backing provides a strong adhesive that allows the felt to be easily applied to a variety of surfaces. This combination of materials makes the felt rolls ideal for a wide range of manufacturing applications.

One of the most common uses for polyester self-adhesive felt rolls with rubber backing is in the production of automotive parts. The felt can be used to line the interior of car doors, providing a sound-proofing barrier that helps reduce noise levels inside the vehicle. The felt can also be used to line the interior of car trunks, providing a cushioning layer that helps protect items stored in the trunk.

The felt rolls can also be used in the production of furniture. The felt can be used to line the interior of drawers and cabinets, providing a soft, cushioning layer that helps protect items stored inside. The felt can also be used to line the interior of chairs and sofas, providing a comfortable surface that helps reduce fatigue and discomfort.

The felt rolls can also be used in the production of clothing. The felt can be used to line the interior of jackets and coats, providing a soft, cushioning layer that helps protect the wearer from the elements. The felt can also be used to line the interior of shoes, providing a comfortable surface that helps reduce fatigue and discomfort.

The felt rolls can also be used in the production of electronics. The felt can be used to line the interior of electronic devices, providing a soft, cushioning layer that helps protect the device from damage. The felt can also be used to line the interior of computer cases, providing a comfortable surface that helps reduce fatigue and discomfort.

The felt rolls can also be used in the production of medical equipment. The felt can be used to line the interior of medical devices, providing a soft, cushioning layer that helps protect the device from damage. The felt can also be used to line the interior of medical beds, providing a comfortable surface that helps reduce fatigue and discomfort.

Polyester self-adhesive felt rolls with rubber backing are revolutionizing the manufacturing industry, allowing manufacturers to produce higher quality products with greater efficiency. This innovative material is helping to make the manufacturing process faster, easier, and more cost-effective, allowing manufacturers to produce more products in less time.

Exploring the Benefits of Using Polyester Self-Adhesive Felt Rolls with Rubber Backing in Chinese Factories

The use of polyester self-adhesive felt rolls with rubber backing in Chinese factories has become increasingly popular in recent years. This is due to the many benefits that these rolls offer to manufacturers. In this article, we will explore the advantages of using polyester self-adhesive felt rolls with rubber backing in Chinese factories.

One of the primary benefits of using polyester self-adhesive felt rolls with rubber backing in Chinese factories is their durability. The rubber backing provides a strong and reliable bond between the felt and the surface it is applied to, making it resistant to wear and tear. This makes it ideal for use in factories where there is a lot of movement and vibration. Additionally, the felt is resistant to water, oil, and other liquids, making it suitable for use in wet environments.

Another advantage of using polyester self-adhesive felt rolls with rubber backing in Chinese factories is their cost-effectiveness. The rolls are relatively inexpensive compared to other materials, making them an attractive option for manufacturers. Additionally, the rolls are easy to install and require minimal maintenance, which helps to reduce labor costs.

The use of polyester self-adhesive felt rolls with rubber backing in Chinese factories also offers a number of safety benefits. The felt is non-slip, which helps to reduce the risk of slips and falls in the workplace. Additionally, the felt is fire-resistant, making it suitable for use in areas where there is a risk of fire.

Finally, the use of polyester self-adhesive felt rolls with rubber backing in Chinese factories is beneficial for the environment. The felt is made from recycled materials, making it an eco-friendly option. Additionally, the felt is non-toxic, making it safe for use in areas where there is a risk of exposure to hazardous chemicals.

In conclusion, the use of polyester self-adhesive felt rolls with rubber backing in Chinese factories offers a number of benefits to manufacturers. The rolls are durable, cost-effective, safe, and eco-friendly, making them an attractive option for many factories.

Comparing the Quality of White and Green Polyester Self-Adhesive Felt Rolls with Rubber Backing Manufactured in Chinese Factories

The quality of polyester self-adhesive felt rolls with rubber backing manufactured in Chinese factories is an important factor to consider when making a purchase. This article will compare the quality of white and green polyester self-adhesive felt rolls with rubber backing manufactured in Chinese factories.

The first factor to consider when comparing the quality of white and green polyester self-adhesive felt rolls with rubber backing manufactured in Chinese factories is the adhesive strength. The adhesive strength of the white felt rolls is typically higher than that of the green felt rolls. This is because the white felt rolls are made with a higher quality adhesive that is more resistant to wear and tear. Additionally, the white felt rolls are more resistant to water and other liquids, making them more durable and long-lasting.

The second factor to consider is the thickness of the felt rolls. The white felt rolls are typically thicker than the green felt rolls. This is because the white felt rolls are made with a higher quality material that is more resistant to tearing and wear. Additionally, the white felt rolls are more resistant to heat and other environmental factors, making them more durable and long-lasting.

The third factor to consider is the rubber backing of the felt rolls. The rubber backing of the white felt rolls is typically thicker and more durable than the rubber backing of the green felt rolls. This is because the white felt rolls are made with a higher quality rubber that is more resistant to wear and tear. Additionally, the white felt rolls are more resistant to water and other liquids, making them more durable and long-lasting.

In conclusion, when comparing the quality of white and green polyester self-adhesive felt rolls with rubber backing manufactured in Chinese factories, the white felt rolls are typically of higher quality than the green felt rolls. This is due to the higher quality adhesive, thicker felt material, and thicker rubber backing used in the production of the white felt rolls.