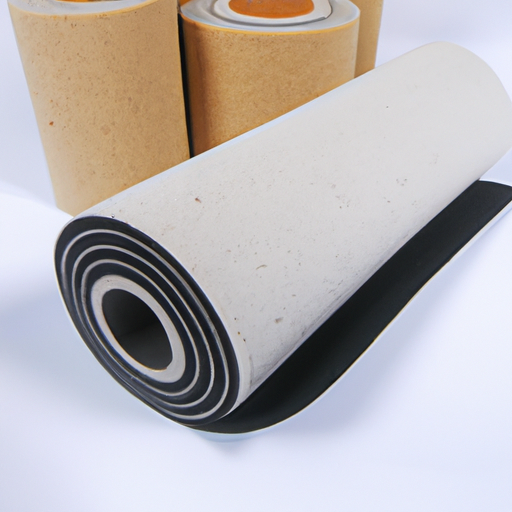

Protective felt rolls for laminating rolls at the ends manufactured by high-end manufacturers

Table of Contents

How Protective Felt Rolls for Laminating Rolls Can Help Improve Your Product Quality

Protective felt rolls for laminating rolls are an essential tool for any business that produces laminated products. These rolls provide a layer of protection between the laminating roll and the product being laminated, ensuring that the product is not damaged during the lamination process. This layer of protection helps to improve the quality of the finished product, as it prevents scratches, dents, and other imperfections from occurring.

The protective felt rolls are made from a soft, non-abrasive material that is designed to protect the product from any damage that may occur during the lamination process. This material is also designed to be heat resistant, so it can withstand the high temperatures used during the lamination process. The felt rolls are also designed to be durable, so they can be used multiple times without needing to be replaced.

The protective felt rolls also help to reduce the amount of time needed to complete the lamination process. By providing a layer of protection between the laminating roll and the product, the lamination process can be completed more quickly and efficiently. This helps to reduce the amount of time needed to complete the lamination process, which can help to improve the overall quality of the finished product.

In addition to providing a layer of protection between the laminating roll and the product, the protective felt rolls also help to reduce the amount of waste produced during the lamination process. By providing a layer of protection between the laminating roll and the product, the amount of waste produced during the lamination process is reduced. This helps to reduce the amount of waste that is produced during the lamination process, which can help to improve the overall quality of the finished product.

Overall, protective felt rolls for laminating rolls are an essential tool for any business that produces laminated products. These rolls provide a layer of protection between the laminating roll and the product, ensuring that the product is not damaged during the lamination process. This layer of protection helps to improve the quality of the finished product, as it prevents scratches, dents, and other imperfections from occurring. Additionally, the protective felt rolls help to reduce the amount of time needed to complete the lamination process, as well as the amount of waste produced during the lamination process. By using protective felt rolls for laminating rolls, businesses can ensure that their products are of the highest quality possible.

The Benefits of Using High-End Manufacturers for Protective Felt Rolls for Laminating Rolls

Using high-end manufacturers for protective felt rolls for laminating rolls is a great way to ensure that your laminating rolls are of the highest quality and will last for a long time. Protective felt rolls are used to protect the laminating rolls from dust, dirt, and other debris that can damage the rolls and reduce their lifespan. High-end manufacturers use the best materials and processes to ensure that their protective felt rolls are of the highest quality and will provide the best protection for your laminating rolls.

One of the main benefits of using high-end manufacturers for protective felt rolls is that they are designed to last. High-end manufacturers use high-quality materials that are designed to withstand the wear and tear of regular use. This means that your protective felt rolls will last longer and provide better protection for your laminating rolls. Additionally, high-end manufacturers use advanced manufacturing processes to ensure that their protective felt rolls are of the highest quality and will provide the best protection for your laminating rolls.

Another benefit of using high-end manufacturers for protective felt rolls is that they are designed to be easy to use. High-end manufacturers use advanced manufacturing processes to ensure that their protective felt rolls are easy to install and use. This means that you can quickly and easily install your protective felt rolls and get the best protection for your laminating rolls. Additionally, high-end manufacturers use advanced manufacturing processes to ensure that their protective felt rolls are easy to clean and maintain. This means that you can keep your protective felt rolls in top condition and ensure that they provide the best protection for your laminating rolls.

Finally, using high-end manufacturers for protective felt rolls is a great way to ensure that your laminating rolls are of the highest quality and will last for a long time. High-end manufacturers use the best materials and processes to ensure that their protective felt rolls are of the highest quality and will provide the best protection for your laminating rolls. Additionally, high-end manufacturers use advanced manufacturing processes to ensure that their protective felt rolls are easy to install and use, easy to clean and maintain, and provide the best protection for your laminating rolls.