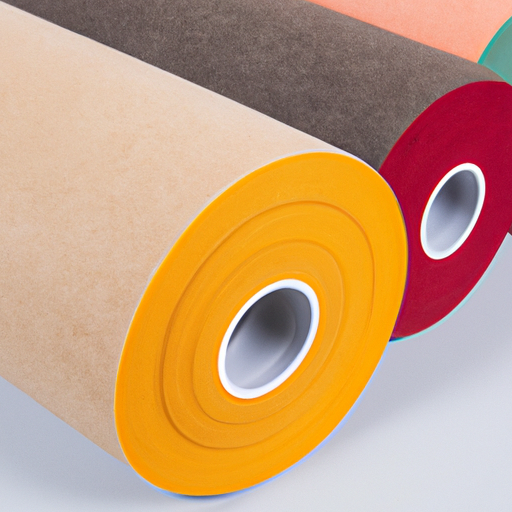

Self adhesive felt roll Velvet polypropylene felt roll Chinese factory production, manufacturing and wholesale,

Table of Contents

Exploring the Benefits of Using Self Adhesive Felt Roll in Manufacturing

Self-adhesive felt roll is a versatile material that is used in a variety of manufacturing processes. It is a cost-effective and efficient way to protect surfaces, reduce noise, and provide insulation. This article will explore the benefits of using self-adhesive felt roll in manufacturing.

First, self-adhesive felt roll is an effective way to protect surfaces. It is often used to line the interior of cabinets, drawers, and other enclosures to protect them from scratches and other damage. It is also used to line the edges of furniture and other items to prevent them from being scratched or dented. The felt roll is easy to apply and can be cut to fit any size or shape.

Second, self-adhesive felt roll is an effective way to reduce noise. It is often used to line the walls of soundproof rooms and other areas where noise needs to be reduced. The felt roll absorbs sound waves, reducing the amount of noise that is transmitted. This makes it an ideal material for soundproofing applications.

Third, self-adhesive felt roll is an effective way to provide insulation. It is often used to line the walls of refrigerators and freezers to keep the temperature inside the appliance consistent. The felt roll also helps to reduce energy costs by preventing heat from escaping.

Finally, self-adhesive felt roll is an economical material. It is relatively inexpensive and can be purchased in large rolls, making it a cost-effective solution for many manufacturing processes.

In conclusion, self-adhesive felt roll is a versatile material that is used in a variety of manufacturing processes. It is an effective way to protect surfaces, reduce noise, and provide insulation. It is also an economical material that can be purchased in large rolls, making it a cost-effective solution for many manufacturing processes.

How Chinese Factories are Utilizing Velvet Polypropylene Felt Roll in Production

In recent years, Chinese factories have been increasingly utilizing velvet polypropylene felt roll in their production processes. This material is a type of non-woven fabric that is made from polypropylene fibers. It is soft and has a velvet-like texture, making it ideal for a variety of applications.

The velvet polypropylene felt roll is used in a variety of industries, including automotive, furniture, and apparel. In the automotive industry, it is used to make car seat covers, door panels, and other interior components. In the furniture industry, it is used to make cushions, mattresses, and other upholstery items. In the apparel industry, it is used to make clothing, hats, and other accessories.

The velvet polypropylene felt roll is also used in the manufacturing of industrial products. It is used to make gaskets, seals, and other components that require a soft, flexible material. It is also used to make filtration products, such as air filters and water filters.

The velvet polypropylene felt roll is highly durable and resistant to wear and tear. It is also resistant to chemicals, making it ideal for use in industrial applications. It is also lightweight and easy to work with, making it a cost-effective material for factories.

The velvet polypropylene felt roll is also environmentally friendly. It is made from recycled materials, making it a sustainable choice for factories. It is also recyclable, making it an even more eco-friendly option.

Overall, Chinese factories are increasingly utilizing velvet polypropylene felt roll in their production processes due to its versatility, durability, and environmental friendliness. This material is an ideal choice for a variety of industries and applications, making it a cost-effective and sustainable option for factories.

Analyzing the Impact of Wholesale Self Adhesive Felt Roll on the Chinese Manufacturing Industry

The Chinese manufacturing industry has experienced a significant shift in recent years, with the introduction of wholesale self adhesive felt roll. This new product has had a profound impact on the industry, and it is important to understand the implications of this development.

Wholesale self adhesive felt roll is a type of felt material that is coated with an adhesive on one side. This adhesive allows the felt to be easily attached to a variety of surfaces, making it a versatile and cost-effective material for a wide range of applications. The material is lightweight, durable, and easy to work with, making it an ideal choice for many manufacturing processes.

The introduction of wholesale self adhesive felt roll has had a number of positive impacts on the Chinese manufacturing industry. First, the material is significantly cheaper than traditional felt materials, making it more cost-effective for manufacturers to use. This has allowed them to reduce their production costs, resulting in increased profits. Additionally, the material is easier to work with than traditional felt, allowing manufacturers to produce products more quickly and efficiently. This has resulted in increased productivity and improved quality control.

Furthermore, the introduction of wholesale self adhesive felt roll has allowed manufacturers to produce products with greater precision and accuracy. This has enabled them to produce higher quality products, which has resulted in increased customer satisfaction and loyalty. Additionally, the material is more durable than traditional felt, meaning that products made with it are more likely to last longer and require less maintenance. This has resulted in increased customer satisfaction and loyalty, as well as increased profits for manufacturers.

In conclusion, the introduction of wholesale self adhesive felt roll has had a significant impact on the Chinese manufacturing industry. The material is significantly cheaper than traditional felt, allowing manufacturers to reduce their production costs and increase their profits. Additionally, the material is easier to work with, resulting in increased productivity and improved quality control. Finally, the material is more durable than traditional felt, resulting in increased customer satisfaction and loyalty. All of these factors have contributed to the success of the Chinese manufacturing industry in recent years.