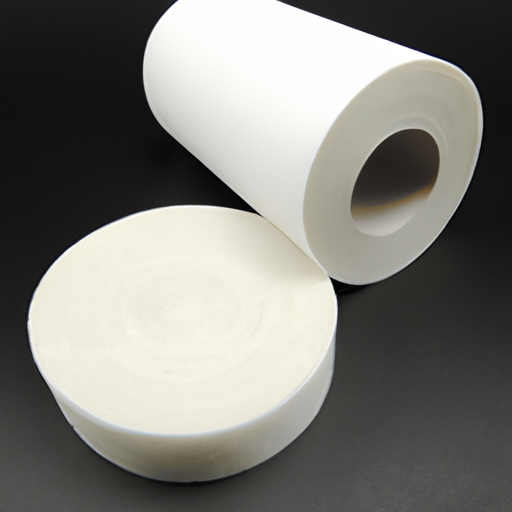

Viscous and elastic white secretion felt roll backing adhesive made in Chinese factories,

Table of Contents

Exploring the Benefits of Viscous and Elastic White Secretion Felt Roll Backing Adhesive Made in Chinese Factories

The use of viscous and elastic white secretion felt roll backing adhesive made in Chinese factories has become increasingly popular in recent years due to its many benefits. This type of adhesive is used in a variety of industries, including automotive, construction, and furniture manufacturing. It is a cost-effective and reliable solution for many applications.

Viscous and elastic white secretion felt roll backing adhesive is made from a combination of natural rubber and synthetic polymers. This combination creates a strong bond that is resistant to temperature changes, moisture, and other environmental factors. The adhesive is also highly flexible, allowing it to be used in a variety of applications.

The adhesive is also highly resistant to abrasion and wear, making it an ideal choice for applications that require a long-lasting bond. Additionally, the adhesive is non-toxic and non-flammable, making it safe to use in a variety of settings.

The adhesive is also easy to apply and remove, making it a great choice for applications that require frequent repairs or adjustments. Additionally, the adhesive is easy to clean and maintain, making it a great choice for applications that require frequent cleaning.

The adhesive is also highly cost-effective, making it an attractive option for businesses looking to save money. Additionally, the adhesive is made in Chinese factories, meaning that it is produced in a cost-effective manner. This makes it an ideal choice for businesses looking to reduce their costs.

Overall, viscous and elastic white secretion felt roll backing adhesive made in Chinese factories is an excellent choice for a variety of applications. It is cost-effective, reliable, and easy to use, making it an ideal choice for businesses looking to save money and time.

Analyzing the Quality of Viscous and Elastic White Secretion Felt Roll Backing Adhesive Made in Chinese Factories

The quality of viscous and elastic white secretion felt roll backing adhesive made in Chinese factories is an important factor to consider when purchasing these products. It is essential to understand the quality of the adhesive in order to ensure that it will perform as expected and provide the desired results.

In order to analyze the quality of the adhesive, it is important to consider several factors. First, the adhesive should be tested for its viscosity. This can be done by measuring the time it takes for the adhesive to flow from a container. The viscosity should be consistent and should not vary significantly over time.

Second, the adhesive should be tested for its elasticity. This can be done by measuring the amount of force required to stretch the adhesive. The elasticity should be consistent and should not vary significantly over time.

Third, the adhesive should be tested for its adhesion. This can be done by measuring the amount of force required to remove the adhesive from a surface. The adhesion should be consistent and should not vary significantly over time.

Fourth, the adhesive should be tested for its durability. This can be done by measuring the amount of time it takes for the adhesive to degrade when exposed to various environmental conditions. The durability should be consistent and should not vary significantly over time.

Finally, the adhesive should be tested for its compatibility with other materials. This can be done by measuring the amount of force required to bond the adhesive to other materials. The compatibility should be consistent and should not vary significantly over time.

By analyzing the quality of viscous and elastic white secretion felt roll backing adhesive made in Chinese factories, it is possible to ensure that the adhesive will perform as expected and provide the desired results. It is important to consider all of the factors mentioned above in order to ensure that the adhesive is of the highest quality.

Comparing the Cost of Viscous and Elastic White Secretion Felt Roll Backing Adhesive Made in Chinese Factories to Other Adhesives

When it comes to adhesives, there are a variety of options available on the market. Two of the most popular types of adhesives are viscous and elastic white secretion felt roll backing adhesive, both of which are made in Chinese factories. It is important to compare the cost of these adhesives to other types of adhesives in order to determine which is the most cost-effective option.

Viscous white secretion felt roll backing adhesive is a type of adhesive that is made from a combination of synthetic rubber and polyvinyl chloride. This type of adhesive is often used for applications such as bonding felt, foam, and other materials. It is typically sold in rolls and is relatively inexpensive compared to other types of adhesives.

Elastic white secretion felt roll backing adhesive is a type of adhesive that is made from a combination of synthetic rubber and polyvinyl chloride. This type of adhesive is often used for applications such as bonding felt, foam, and other materials. It is typically sold in rolls and is more expensive than viscous white secretion felt roll backing adhesive.

When comparing the cost of these two types of adhesives to other types of adhesives, it is important to consider the cost of the adhesive itself as well as the cost of the application process. Viscous white secretion felt roll backing adhesive is typically less expensive than elastic white secretion felt roll backing adhesive, but the application process may be more expensive due to the need for additional tools and materials.

In conclusion, when comparing the cost of viscous and elastic white secretion felt roll backing adhesive made in Chinese factories to other adhesives, it is important to consider the cost of the adhesive itself as well as the cost of the application process. Viscous white secretion felt roll backing adhesive is typically less expensive than elastic white secretion felt roll backing adhesive, but the application process may be more expensive due to the need for additional tools and materials.