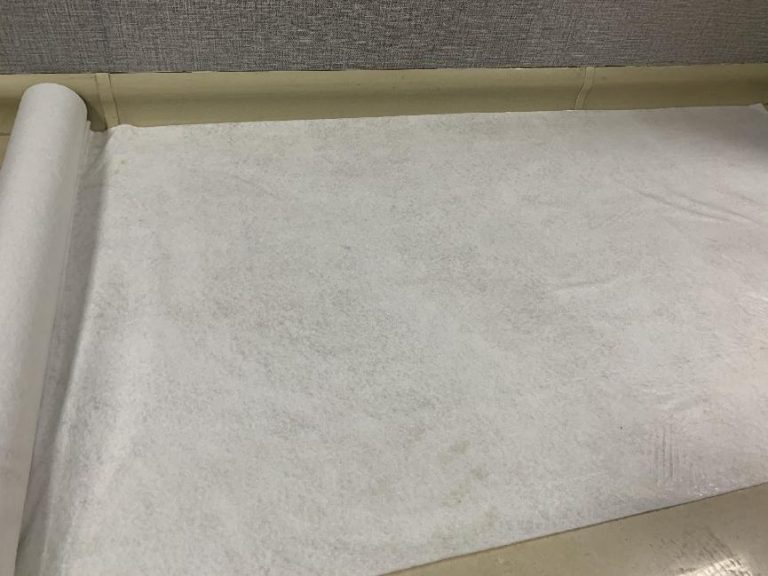

white felt floor protection when laying, asphalt roofing felt rolls made in china

Table of Contents

Do you know how many names there are for floor protection felt rolls?

According to the different cultural attributes of each country, there are many different names. Let me give you some popular science. Floor protection film is also called paint adhesive felt roll, stair adhesive felt roll, floor adhesive felt roll, white felt roll, white glue wool felt roll, laminated coating adhesive felt roll, wool felt roll with adhesive, adhesive felt roll with backing, PE film laminated adhesive wool felt, white polyester fiber adhesive wool felt, which is the most commonly used name in European and American customers’ purchases.

Do you know the uses of white stair protection felt rolls?

White self-adhesive wool felt roll is the most common auxiliary material product in the decoration industry. It plays an important role in environmental protection for home decoration or large-scale team decoration renovation, but with the development of the industry and the deepening of product categories, more and more quality problems are also common. The decoration industry standards of each country are different, so the quality requirements of the product

According to the different requirements of each country, how many types of laminated adhesive felt are there?

- In the Chinese market, most of them use woven fabric as the top covering layer, and the side in contact with the floor tiles will use pearl cotton, geotextile, recycled non-woven cotton as the base material and laminated with woven fabric. Most of these materials have a pungent smell and are not environmentally friendly, and the woven fabric is easily damaged in harsh construction environments, which will have a serious impact on the construction process. During construction, the gaps in the protective film need to be glued with tape to avoid slipping during the construction process and the disadvantage of not being able to achieve rapid layout. Due to its low price, it will still be adopted by most construction teams.

- The European and American markets use polyethylene film as the top covering layer, which is laminated with pure raw materials based on polyester fiber. However, unlike the Chinese floor protection felt roll, the back is coated with acrylic glue and finally dried and cured. Because of the unique properties of the polyethylene film, it has good lateral and longitudinal tensile strength, is not easily damaged, and can even be reused according to the construction environment. The glue used is white, odorless, non-toxic and meets the environmental protection standards of the European and American markets. During construction, it will be bonded to the floor when opened in the forward direction, which is convenient for construction workers to quickly lay out the effect, and there will be no glue residue on the floor after the construction is completed. It protects the environment and improves construction efficiency. Of course, due to its complex manufacturing process and high product quality, the price will be slightly higher.