Wholesaler of needle punched polyester felt vs. acrylic felt thick felt rolls in Chinese factories,

Table of Contents

Exploring the Benefits of Needle Punched Polyester Felt vs. Acrylic Felt Thick Felt Rolls in Chinese Factories

The use of needle punched polyester felt and acrylic felt thick felt rolls in Chinese factories is becoming increasingly popular. Both materials offer a variety of benefits, but it is important to understand the differences between them in order to make an informed decision about which material is best for a particular application. This article will explore the benefits of needle punched polyester felt and acrylic felt thick felt rolls in Chinese factories.

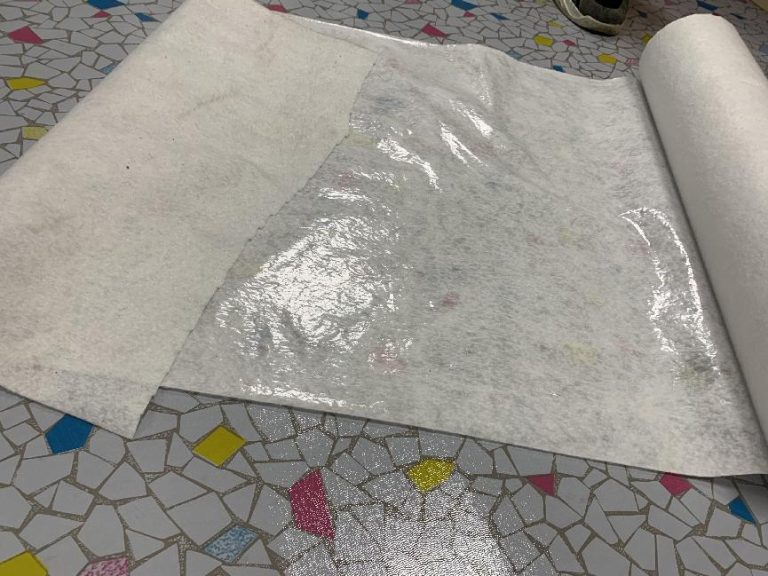

Needle punched polyester felt is a strong, durable material that is resistant to abrasion and tearing. It is also highly resistant to water, making it an ideal choice for applications that require protection from moisture. Additionally, needle punched polyester felt is lightweight and easy to work with, making it a popular choice for many industrial applications.

Acrylic felt thick felt rolls are also a popular choice for industrial applications in Chinese factories. This material is highly resistant to heat and chemicals, making it an ideal choice for applications that require protection from extreme temperatures or harsh chemicals. Additionally, acrylic felt thick felt rolls are lightweight and easy to work with, making them a popular choice for many industrial applications.

When it comes to cost, needle punched polyester felt is generally more expensive than acrylic felt thick felt rolls. However, the cost difference is often offset by the superior performance of needle punched polyester felt. Additionally, needle punched polyester felt is often more durable than acrylic felt thick felt rolls, making it a better choice for applications that require long-term performance.

In conclusion, both needle punched polyester felt and acrylic felt thick felt rolls offer a variety of benefits for industrial applications in Chinese factories. Needle punched polyester felt is generally more expensive than acrylic felt thick felt rolls, but it offers superior performance and durability. Acrylic felt thick felt rolls are more affordable, but they are not as durable as needle punched polyester felt. Ultimately, the choice between the two materials should be based on the specific application and the desired performance.

Analyzing the Cost-Effectiveness of Needle Punched Polyester Felt vs. Acrylic Felt Thick Felt Rolls in Chinese Factories

The cost-effectiveness of needle punched polyester felt versus acrylic felt thick felt rolls in Chinese factories is an important consideration for manufacturers. In order to make an informed decision, it is important to understand the differences between the two materials and the advantages and disadvantages of each.

Needle punched polyester felt is a synthetic material made from polyester fibers that are punched together with needles. This material is lightweight, durable, and resistant to abrasion and tearing. It is also resistant to water, oil, and chemicals, making it an ideal choice for industrial applications. Additionally, needle punched polyester felt is relatively inexpensive and easy to work with.

Acrylic felt thick felt rolls are made from acrylic fibers that are woven together. This material is heavier and more durable than needle punched polyester felt, making it a better choice for applications that require a higher level of protection. Acrylic felt is also more expensive than needle punched polyester felt, but it is more resistant to wear and tear and can last longer.

When it comes to cost-effectiveness, needle punched polyester felt is generally the more cost-effective option for Chinese factories. This is due to its lower cost and its ability to withstand wear and tear. Additionally, needle punched polyester felt is easier to work with and can be used in a variety of applications.

On the other hand, acrylic felt thick felt rolls are more expensive and may be more suitable for applications that require a higher level of protection. Additionally, acrylic felt is more resistant to wear and tear and can last longer. However, it is important to consider the cost of the material when making a decision, as acrylic felt is more expensive than needle punched polyester felt.

In conclusion, when it comes to cost-effectiveness, needle punched polyester felt is generally the more cost-effective option for Chinese factories. This is due to its lower cost and its ability to withstand wear and tear. However, it is important to consider the cost of the material when making a decision, as acrylic felt is more expensive than needle punched polyester felt. Ultimately, the decision should be based on the specific needs of the application and the budget of the manufacturer.

Comparing the Quality of Needle Punched Polyester Felt vs. Acrylic Felt Thick Felt Rolls in Chinese Factories

When it comes to choosing the right felt material for a project, it is important to consider the quality of the material. In Chinese factories, two of the most popular felt materials are needle punched polyester felt and acrylic felt thick felt rolls. Both materials have their own unique advantages and disadvantages, and it is important to understand the differences between them in order to make an informed decision.

Needle punched polyester felt is a strong and durable material that is often used for industrial applications. It is resistant to abrasion and can withstand high temperatures. It is also resistant to water and chemicals, making it an ideal choice for projects that require a waterproof material. The downside of needle punched polyester felt is that it is not as soft as acrylic felt, and it can be difficult to work with.

Acrylic felt thick felt rolls are softer and more pliable than needle punched polyester felt. They are also more affordable, making them a popular choice for craft projects. However, acrylic felt is not as durable as needle punched polyester felt and is not as resistant to water and chemicals. It is also not as strong, so it may not be suitable for projects that require a strong material.

When it comes to the quality of needle punched polyester felt and acrylic felt thick felt rolls in Chinese factories, both materials are of good quality. However, needle punched polyester felt is generally considered to be of higher quality due to its strength and durability. Acrylic felt is a good choice for craft projects, but it may not be suitable for industrial applications. Ultimately, the choice of material should be based on the specific requirements of the project.